logo cadagua

What We Do

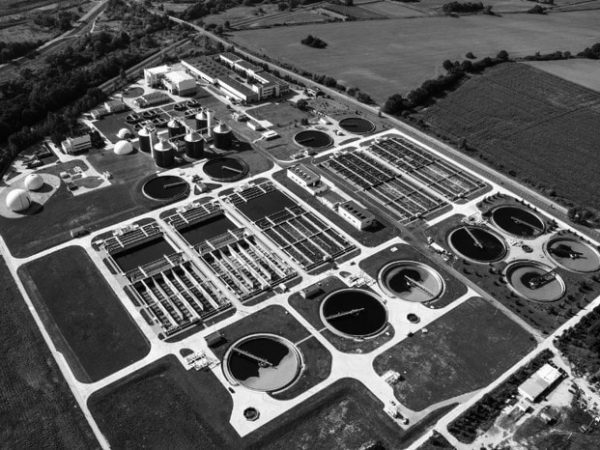

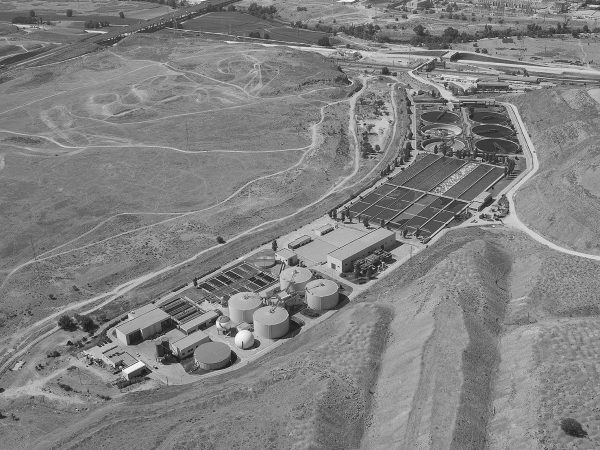

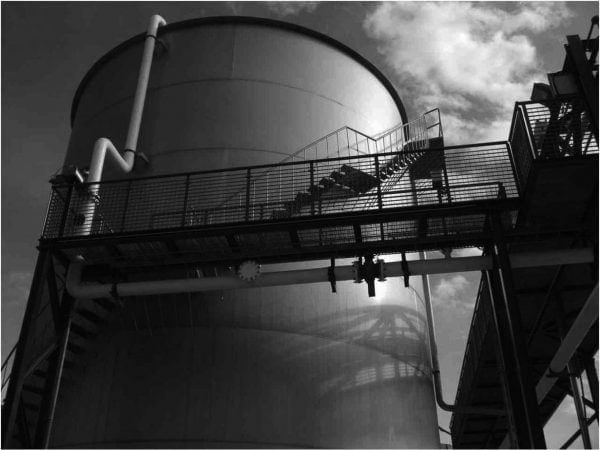

We design, build, and operate water treatment and purification facilities.

We have been developing purification, potabilization, and desalination technologies of the highest quality and with the utmost respect for the environment for almost 50 years. Particularly noteworthy among our concessions and other long-term contracts are the desalination plants in Ceuta, Melilla, Al Ghubrah, Aguilas-Guadalentín, Valdelentisco and Alicante, as well as the Utebo sewage treatment plant in Zaragoza.

Cadagua

Main Figures

-

ENERGY GEN

35%

ELECTRIC ENERGY CONSUMED

-

22,650,114Nm³

Biogas generated

-

271,264,700m³

water treated

-

271,128,095m³

water made drinkable

-

Waste recovery

39%

of influents

-

96%

recovered sludge

Our Operation and Maintenance specialists ensure the continual improvement of processes and promote implementing improvements for both new projects and plants that are in operation.

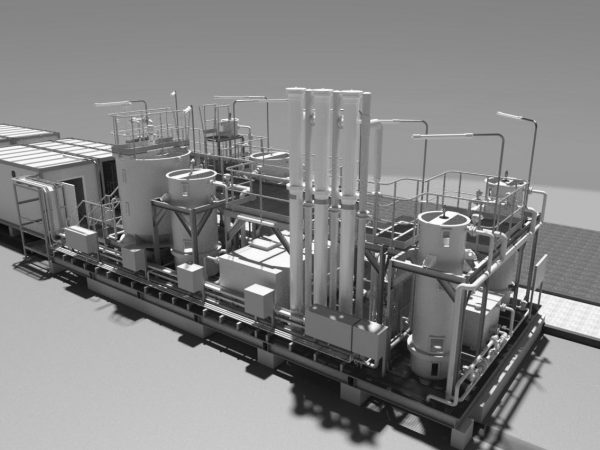

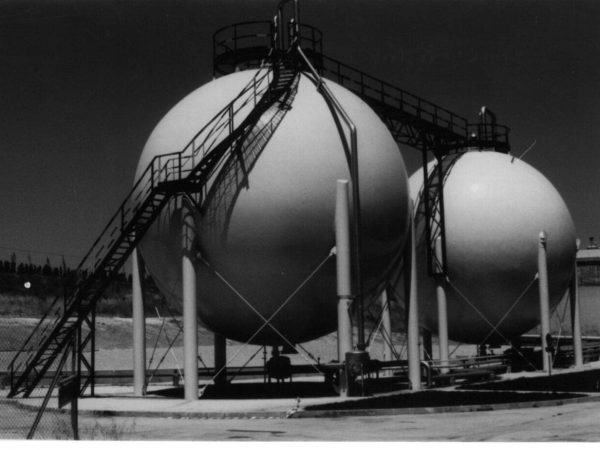

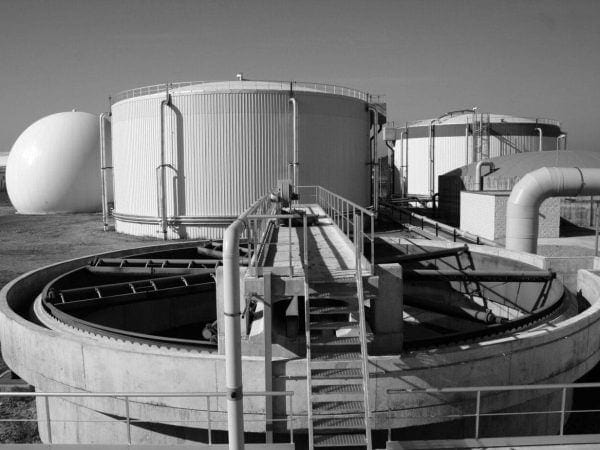

Our projects include water treatment centers for human consumption (WTC), wastewater treatment plants (WWTP), industrial wastewater treatment plants (IWWTP), ocean water desalination facilities (OWDF), also called desalination plants, and thermal sludge drying plants for urban treatment facilities. These drying plants are often integrated directly into WWTPs and have important security systems.

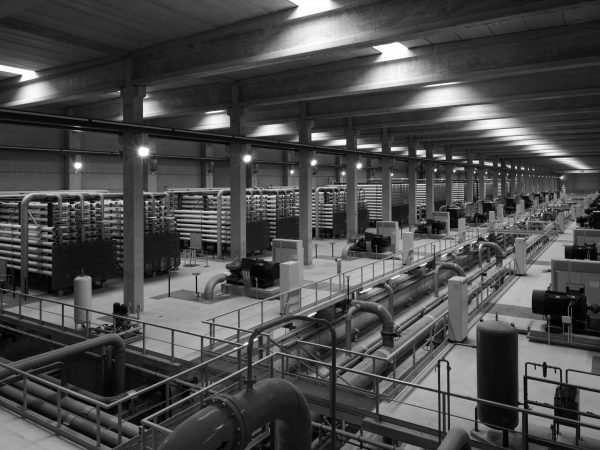

The desalination plants have reverse osmosis technology, which we are recognized worldwide.

Activities

Learn About Our Areas of Expertise

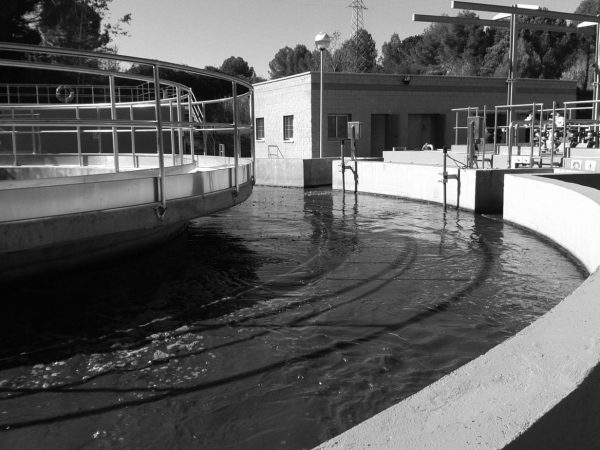

Wastewater Treatment

Innovation, circular economy and minimization of impacts are the drivers of our design.

Water Treatment

The most advanced technologies guarantee the most demanding challenges in our DWTP.

Know more

Water Desalination

Our SWRO guarantee water supply with the minimum impact and energy consumption.

Know more

Industrial Water

Leaders in industrial effluent treatment via anaerobic low carbon footprint technology.

Know more

Thermal Drying

Leaders in installed capacity, both number of plants built and operated.

Know more

International Experience

The Bens Wastewater Treatment Plant

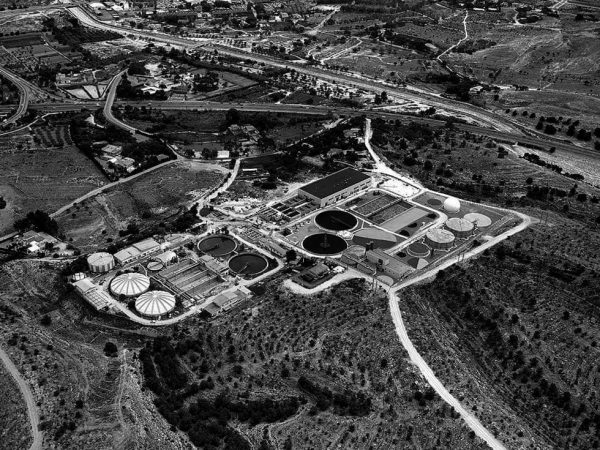

The Bens WWTP treats waster water from the municipalities of A Coruña, Cambre, Culledero, Arteixo, and Oleiros with the aim of complying with the European Union’s directives on water quality. It is undoubtedly one of the most significant sanitation projects carried out in Galicia. It has a pre-treatment facility that can manage up to 6.7 m³/s and a secondary treatment system of 2.3 m³/s. It treats water from a population of about 600,000 residents. After its construction, Cadagua also took over operation and maintenance of the facilities.

Discover the project

Drinking water treatment plant in Wieliszew (Ozone)

- Estación de tratamiento de aguas potables

Modernization of the Wieliszew WTC, one of the facilities with the highest capacity in the country that therefore became Cadagua’s second project on potable water provisioning in Poland. The modernization was carried out with three important interventions:. Pumps: design and execution of three (3) pumps – first raw water pump located on the ETAP plot with a capacity of 260,000 m3/d, and 2nd and 3rd external pumps for treated water located in Warsaw with a unit capacity of 240,000 m3/d. Ozonization: The supply and installation of ozone treatment Filtration: modernization and renovation of the sand filters The WTC treats water coming from the Zegrze reservoir, fed by the Bug and Narew rivers and supplying the northern districts of Warsaw, equivalent to about 30% of the capital.

Drinking water treatment plant in Wieliszew (Filters)

- Estación de tratamiento de aguas potables

Same description as C3U and C4T. Unify

Drinking water treatment plant at Venta Alta

- Estación de tratamiento de aguas potables

The Venta Alta WTC is the primary facility for water potabilization in Bizkaia. Throughout its history, which begins in the year 1968, Cadagua has had a leading role in numerous expansions and modernizations. With the last intervention in 2015, Cadagua has modernized the facilities, with its current treatment capacity at 7 m3/s.

Drinking water treatment plant at Varsovia Centralny

- Estación de tratamiento de aguas potables

Modernization of the Centralny WTC, the oldest potable water Treatment Station in Warsaw, which has supplied over half of the capital’s population since 1886. The Plant, which is designed and built for a volume of 300,000 m3/d, is the second-largest facility in terms of size in the city. Furthermore, the Plant is a leader in the sector, as shown by the fact it was considered a Historic Monument, a designation awarded to the complex of Filtering Buildings by the President of the Republic in 2012. Another feature that makes it an outstanding example across Europe is the combination of modern technologies with original elements that are still operational and which have been meeting guidelines for over 125 years.

Drinking water treatment plant in Wieliszew (Pumps)

- Estación de tratamiento de aguas potables

Same description as C3U. Unify

Seawater desalination plant in Valdelentisco

- Instalación desaladora de agua de mar

The desalinization plant in Valdelentisco, which opened in January 2008, is located near the westernmost border of Rambla de Valdelentisco, between Mazarrón and Cartagena (Murcia). With a current production capacity of 27 hm3/year, which can be raised to 70 hm3/year, this plant has become one of the biggest facilities of its type in the whole world, enabling supply to a part of this autonomous community through the group of municipalities of Canales del Taibilla, as well as for irrigation and urban supply for touristic and residential uses in Campo de Cartagena. Following its design and construction, Cadagua has taken over its Operation and Maintenance, including the last few updates and remodelings to optimize energy usage by means of modern isobaric chamber systems.

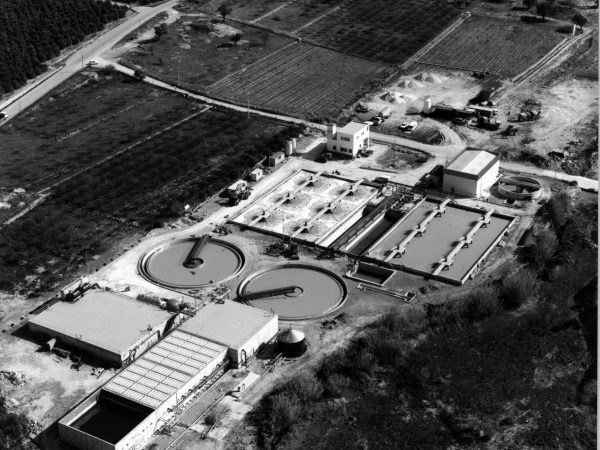

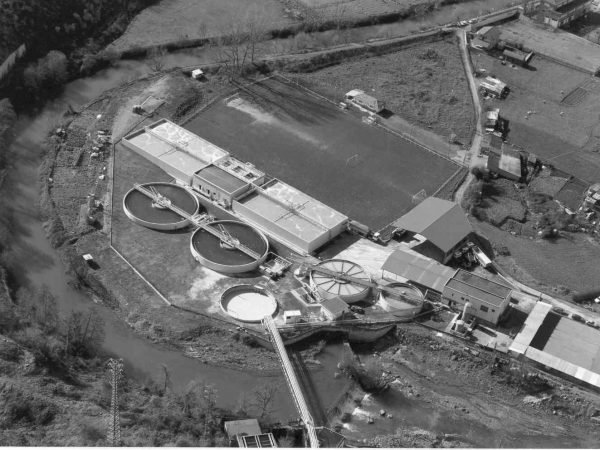

Wastewater treatment plant in Villapérez

- Estación de depuración de aguas residuales

The Villaperez WWTP is part of the sanitation system for the Nora River Basin in the Central Area of Asturias, and it treats discharges from Oviedo, Siero, Noreña, and Llanera. Some of the construction carried out by Cadagua in 1998 was pioneering in Spain, as the plant design incorporated a design for an advanced, versatile, biological removal process for nitrogen and phosphorus, along with energy recovery and thermal drying of digested sludge.

Industrial wastewater treatment plant at UIPSA La Pobla de Claramunt

- Industrial wastewater purification station

Expansion of the treatment capacity of the plant carried out by Cadagua in 2004 by means of a new Biopaq IC anaerobic reactor and aerobic treatment with and secondary decantation.

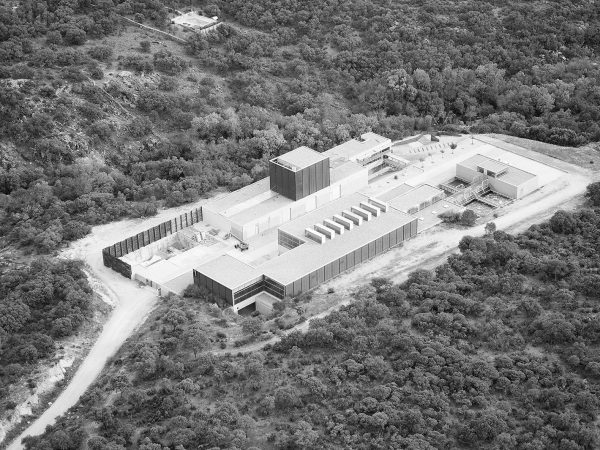

Drinking water treatment plant in Trujillo (Presa Santa Lucía)

- Estación de tratamiento de aguas potables

This intervention guarantees water supply to the 25 municipalities of the group of municipalities of la Presa de Santa Lucía. The population that will benefit from it has been estimated to be over 50,000 residents.

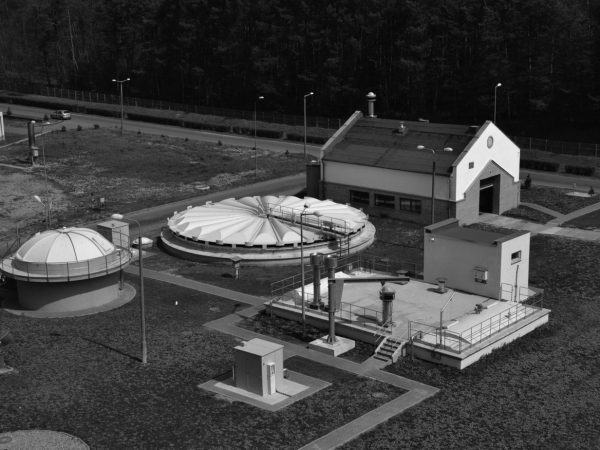

Wastewater treatment plant in Tomaszow Mazowiecki

- Estación de depuración de aguas residuales

Expansion and modernization of the WWTP Tomaszów Mazowiecki, which included the construction of a new WWTP, the substitution of the sewer system between the WWTP and the plant that is approximately 1.3 km long, and the modernization of the sludge line in the WWTP by incorporating thermal drying. The purification system is located in an area with an especially sensitive ecosystem, surrounded by forests and crossed by a dense network of rivers, as well as the protected area Natura 2000, which was awarded the prestigious environmental prize Pantheon of Polish Ecology. The uniqueness of this WWTP is in the moving bed biofilm reactor (MBBR) technology applied and the biological treatment, where the biofilm formed in the middle carrier allows for a high degree of nitrification of wastewater at a temperature of 8°C. The plant has a continual monitoring system that enables dynamic analysis and updating the functioning of the biological part of the WWTP. This system operates autonomously, in parallel, and complement terribly to the WWTP’s SCADA monitoring system.

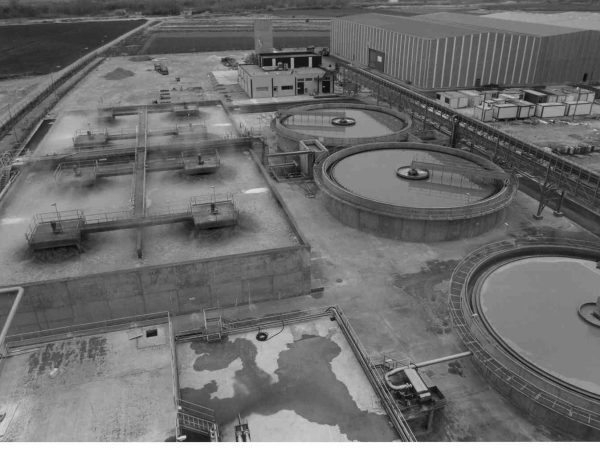

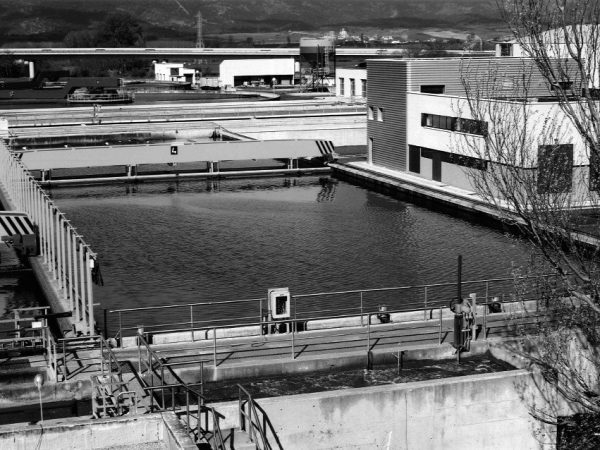

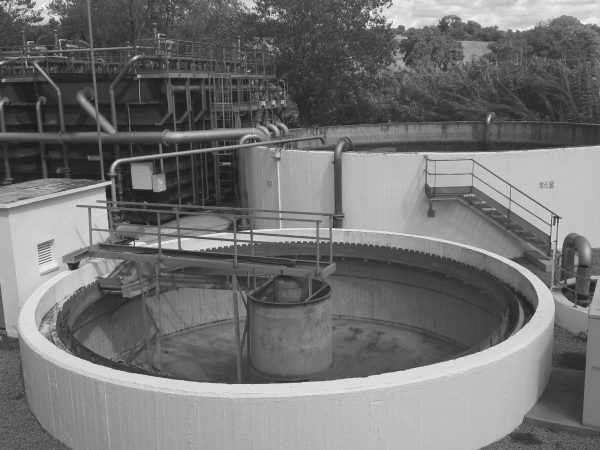

Wastewater treatment plant in Sur Madrid

- Estación de depuración de aguas residuales

The Sur Madrid WWTP, which today has a capacity of over 80 million m3/year, provides service to the districts of Vicalvaro, Puente Vallecas, and Villa de Vallecas in the capital of Madrid, as well as the municipalities of Getafe, Parla, Pinto, Fuenlabrada, and Humanes (approximately 1,000,000 residents). Cadagua participated in its start with the design and construction of the primary clarifier. We’ve also taken over Operation and Maintenance of the treatment system at different points in its history.

Drinking water treatment plant in Sorbe

- Estación de tratamiento de aguas potables

The Sorbe WTC began operations in 1981 with a capacity of 1,000 L/s. In 2003, Cadagua began the expansion with another 1,500 additional L/s. This expansion also included complete modernization of the plant, incorporating, among other things, sludge treatment and new equipment for generation and chemical addition.

Industrial wastewater treatment plant at Smurfit-Kappa Mengibar

- Industrial wastewater purification station

Smurfit-Kappa entrusted Cadagua to expand treatment capacity, changing out an old UASB anaerobic reaction for a modern IC, including an associated line of biogas (gasometer and torch).

Wastewater treatment plant in Tamaraceite and Tenoya

- Estación de depuración de aguas residuales

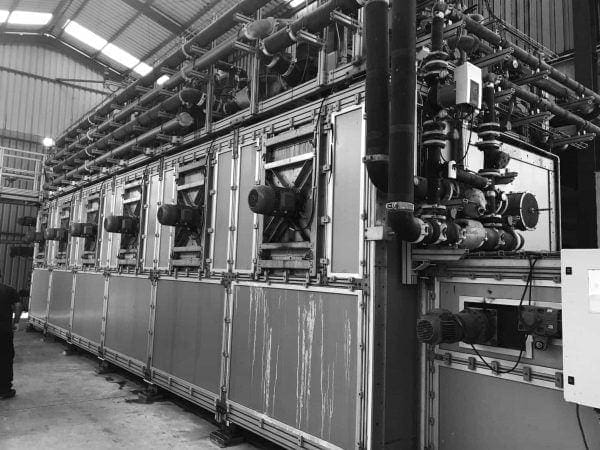

Thanks to this new infrastructure with MBR technology, the city council of las Palmas de Gran Canaria intends to improve management of the complete cycle of water in the municipality, mitigate bad odors from the current WWTP and, and meet the objective of zero discharge of pretreated waters into the sea. At the same time, this will mean significant savings in water for irrigation in the city.

Wastewater treatment plant in Talagante

- Estación de depuración de aguas residuales

Wastewater treatment plant in Szczecinek

- Estación de depuración de aguas residuales

Modernization and construction of the Szczecinek Treatment Station, a project of considerable size valued at over €19 million, an update to the old, inefficient plant currently in existence that was originally designed to serve large-scale industry. The modernization, which consists of building a treatment plant with a treatment capacity of 12,000 m3/d, instead of the original 20,000 m3/d, was co-financed by the European Union and has met projected objectives: biological reduction of nutrients (nitrogen and phosphorus) and decreased operational and maintenance costs.

Wastewater treatment plant in Sant Feliu de Llobregat

- Estación de depuración de aguas residuales

This significant expansion gave the WWTP a nutrient elimination system that reduces the risk of eutrophication for the Llobregat River and the waterfront. Likewise, tertiary treatment by means of ultraviolet and filtration technology was installed in order to reuse part of the water and thereby increase efficiency in managing the zone’s water cycle.

Wastewater treatment plant in Seixal

- Estación de depuración de aguas residuales

The Seixal purification system was Cadagua’s first success in Portugal’s water market. With a capacity of 43,580 m3/day, the WWTP incorporates primary lamella clarifiers and anaerobic digestion of sludge and its energy usage by means of co-generation.

Wastewater treatment plant in Madrid Sur

- Estación de depuración de aguas residuales

- Secado Térmico

This WWTP treats 110,000 T/year of wet sludge (20%MS) generated in the metropolitan region of Madrid through a thermal drying process until reaching a dryness of 90% MS. The dried sludge is used as fertilizer for agricultural purposes. The plant generates 25 MW of electricity that is exported to the grid.

Wastewater treatment plant in Butarque

- Estación de depuración de aguas residuales

- Secado Térmico

It treats 110,000 T/year of wet sludge (20%MS) generated by the WWTPs in the metropolitan region of Madrid through a process of thermal drying until reaching dryness of 90% MS. The dried sludge is used as fertilizer for agricultural purposes. The plant generates 18 MW of electricity that is exported to the grid.

Wastewater treatment plant in Siedlce

- Estación de depuración de aguas residuales

- Secado Térmico

Design and expansion of a new facility for Thermal Drying of Sludge and Co-generation at the WWTP in Siedlce. Cadagua has done excellent work at this facility, achieving the exact equilibrium point between the production of energy derived from using biogas and the energy produced by means of natural gas in the four co-generation units and wholly meeting the demands of the process with respect to the needs for electricity and heat. In addition, the WWTP earned “green” and “yellow” energy licenses, which meant an additional source of income. The Facility for Thermal Drying of Sludge, designed and built by Cadagua, has met the client’s objectives, as it is an exemplary facility that operates properly for 8000 h/year.

Industrial wastewater treatment plant in Sarria de Ter

- Industrial wastewater purification station

A complete purification line with Biopaq IC anaerobic treatment and aerobic treatment from activated sludge as main lines to ensure discharge in the Ter River, complying with all relevant regulations. Likewise, there is tertiary treatment for reusing effluents in manufacturing and biogas washing for burning in boilers.

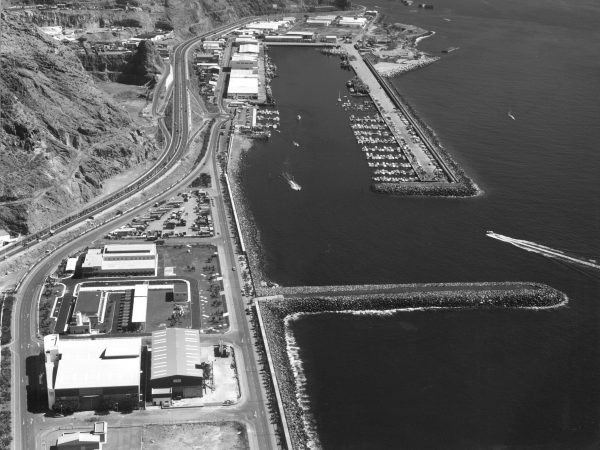

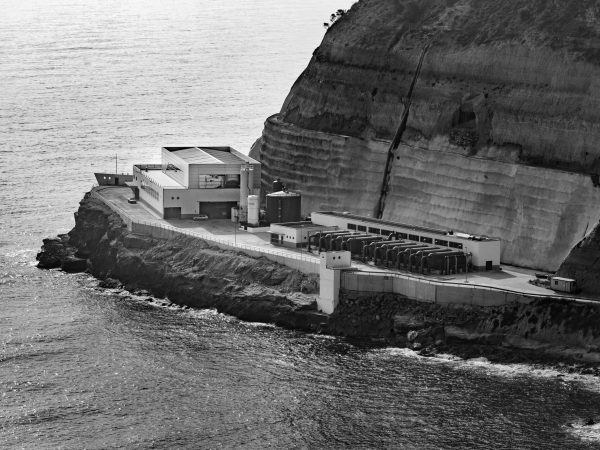

Seawater desalination plant in Santa Cruz de Tenerife

- Instalación desaladora de agua de mar

The Santa Cruz de Tenerife desalinization plant, with its almost 21,000 m3/day covers approximately 40% of the city’s average demand. It was designed and built by Cadagua in 2003.

Drinking water treatment plant in Sant Joan Despí

- Estación de tratamiento de aguas potables

An exemplary project that incorporates advanced refined potabilization treatment by means of UF and OI membranes, a technology that provides a complete barrier for viruses and bacteria and eliminates almost all of the organic and inorganic compounds from the river water.

Industrial wastewater treatment plant at SAICA 2-3-4 (El Burgo de Ebro)

- Industrial wastewater purification station

Since its first intervention in 1992, SAICA has continually relied on Cadagua to carry out 9 capacity expansions at its plants, providing the same as 7 Biopaq IC reactors, with a total capacity of 315,000 Kg DQO each day and biogas washing for 600 Kg of sulfur daily.

Wastewater treatment plant in Ronda

- Estación de depuración de aguas residuales

Since it was inaugurated in 2008, the Ronda WWTP has been a turning point in the conservation of the Guadalevín River’s natural habitat. One especially notable feature is the recovery from the stretch between the city of Ronda and the village of La Indiana. Otters and several species of fish have returned to live in parts of the river that were previously uninhabited because of contamination.

Industrial wastewater treatment plant in SAICA – 4

- Industrial wastewater purification station

Since its first intervention in 1992, SAICA has continually relied on Cadagua to carry out 9 capacity expansions at its plants, providing the same as 7 Biopaq IC reactors, with a total capacity of 315,000 Kg DQO each day and biogas washing for 600 Kg of sulfur daily.

Industrial wastewater treatment plant at SAICA – 1 (expansion)

- Estación de depuración de aguas residuales industriales

Since its first intervention in 1992, SAICA has continually relied on Cadagua to carry out 9 capacity expansions at its plants, providing the same as 7 Biopaq IC reactors, with a total capacity of 315,000 Kg DQO each day and biogas washing for 600 Kg of sulfur daily.

Industrial wastewater treatment plant at SAICA – 1

- Industrial wastewater purification station

Since its first intervention in 1992, SAICA has continually relied on Cadagua to carry out 9 capacity expansions at its plants, providing the same as 7 Biopaq IC reactors, with a total capacity of 315,000 Kg DQO each day and biogas washing for 600 Kg of sulfur daily.

Wastewater treatment plant in Rincón de León

- Estación de depuración de aguas residuales

Since 2006, the Rincón de Leon treatment plant has had an advanced, complete tertiary treatment system that enables up to 30 cubic hectometers of treated wastewater to be reused per year. The water is used to supply the irrigation network for farms in l’Alcanti and Medio Vinalopó. The treatment combines physical-chemical systems, continuous sand filtration, ultrafiltration by means of submerged hollow fiber membranes, reverse osmosis, and ultraviolet light. It is undoubtedly one of the most important highlights in reuse designed, built, and operated by Cadagua.

Industrial wastewater treatment plant at Anaerobic Reactor – Saica 2-3-4

- Industrial wastewater purification station

Since its first intervention in 1992, SAICA has continually relied on Cadagua to carry out 9 capacity expansions at its plants, providing the same as 7 Biopaq IC reactors, with a total capacity of 315,000 Kg DQO each day and biogas washing for 600 Kg of sulfur daily.

Wastewater treatment plant in Ribadesella

- Estación de depuración de aguas residuales

The Ribadesella WWTP is designed to treat an average flow of 7,560 m³/day in peak seasons, and 3,960 m³/d in low seasons. It has a prolonged biological oxidation process aerated by turbines with a maximum treatment capacity of 11,520 m³/day. The treated water goes through an ultraviolet disinfection system before being discharged into the river.

Industrial wastewater treatment plant in Nufri

- Industrial wastewater purification station

Expansions to the existing treatment capacity (SBR) including 2 Biopaq IC anaerobic reactors in later projects.

Drinking water treatment plant at the Bolueta Pilot Plant

- Estación de tratamiento de aguas potables

The Bolueta Pilot Plant is an ambitious research project led by the Consorcio de Aguas for Bilbao Bizkaia. Cadagua is designing, building, and will operate this infrastructure under BIM (Building Information Modeling) philosophy. Among its technological goals, the plant will analyze the future behavior of Venta Alta’s WTC in the purification of Emerging Contaminants.

Drinking water treatment plant in Pilones

- Estación de tratamiento de aguas potables

This treatment plant is located in Arroyo de los Pilones, in the Santa Rosalía area, behind the Andalusia Technology Park, along with the dam of the same name. The water stored in the dam is a guaranteed raw water supply for the city since, from there, we could maintain the supply to the municipality of Málaga for 12 days. A unique feature of this WTC is the radial layout of its 20 pressure sand filters that ensure production of 2,000 L/s.

Drinking water treatment plant in Nanjing

- Estación de tratamiento de aguas potables

Drinking water treatment plant in Ourense

- Estación de tratamiento de aguas potables

This important supply project benefits a population of about 140,000 residents, with a timeline of 50 years. Construction includes collecting and pumping from the Miño River, 4,734 meters of piping, and water treatment of 202 L/s.

Wastewater treatment plant in Munguia

- Estación de depuración de aguas residuales

This project was a vital step for ensuring the sanitation of the Butrón River. Nowadays, thanks to this important WWTP and other important investments made by the Consorcio de Aguas de Bilbao Bizkaia, all water from Laukiniz to Munguía is collected and purified.

Drinking water treatment plant at On Stevens

- Estación de tratamiento de aguas potables

This involves remodeling and new construction of a pump room for the potable water supply for the residents of Corpus Christi. The work involves remodeling the existing pumps as well as their drawing. In addition to the pumps, a new well pump is being built and installed.

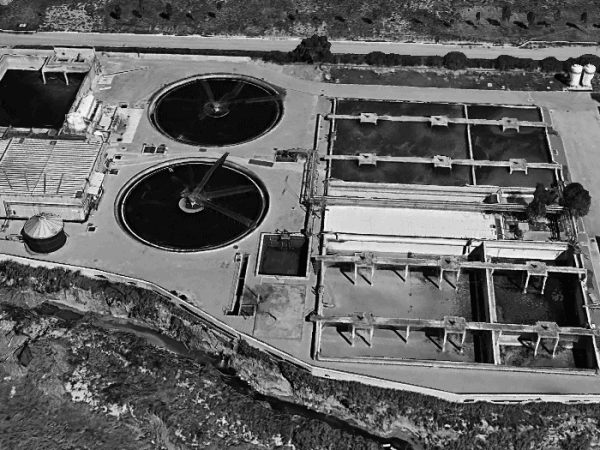

Wastewater treatment plant in Monte Orgegia

- Estación de depuración de aguas residuales

The Monte Orgegia WWTP, with a flow of 60,000 m3/day, has been treating wastewater from Alicante, El Campello, Mutxamel, and Sant Joan d’Alacant for over a decade. This major facility was designed and built by Cadagua and has all the usual purification processes, including nutrient removal, tertiary treatment by filtration, and ultraviolet disinfection and anaerobic stabilization of sludge.

Seawater desalination plant in Jorf Lasfar

- Instalación desaladora de agua de mar

Design and Construction of a seawater desalination plant for the OCP (Office Cherifien des Phosphates), a world leader in the market for phosphates and their derivatives. To combat the difficult conditions of seawater, the desalinization plant incorporates advanced pretreatment including Dissolved Air Flotation and Ultrafiltration. Cadagua took on this ambitious contract as a sole contractor under the turnkey ready mode.

Wastewater treatment plant in Melilla

- Estación de depuración de aguas residuales

- Secado Térmico

Cadagua has over 13 notable projects related to Thermal Sludge Drying purification systems. The thermal drying of the treatment plant in Ciudad Autónoma de Melilla has technology with a low-temperature range and an evaporation capacity of 565 kg of water an hour. The objective of this facility is complementary drying of slurry generated at the treatment plant in order to reach an average drying level greater than the necessary minimum of 50% so that it can be used for energy at the city’s Incineration Plant.

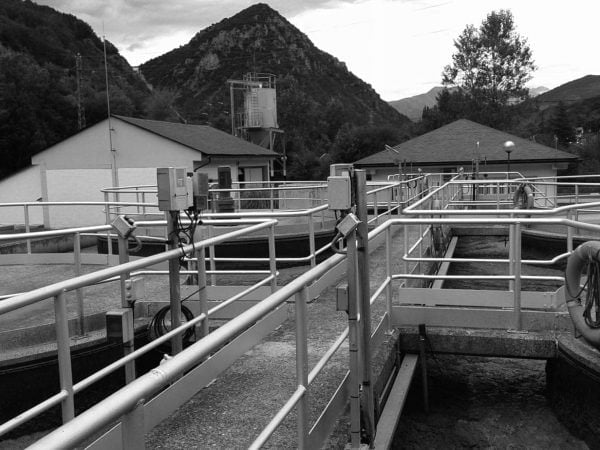

Wastewater treatment plant in Jelenia Gora – Miejska Oczyszczalnia Scieków

- Estación de depuración de aguas residuales

Design and expansion of the WWTP at Jelenia Góra, located in the south of Poland next to the Karkonosze National Park. This construction expanded the plant’s treatment capacity to 25,000 m3/d, gave it greater flexibility, and improved the guarantees for the water treated and deodorizing of the facility by means of building the second biological treatment line.

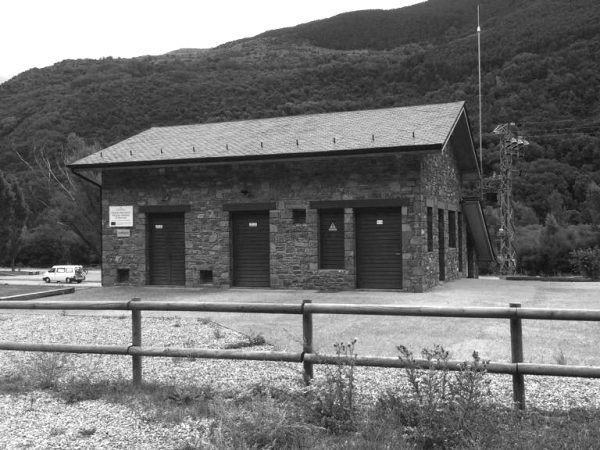

Drinking water treatment plant in Jelenia Gora

- Estación de tratamiento de aguas potables

The Jelenia Góra WTC is Cadagua’s first construction project in Poland, located in the south of the country, near the Karkonosze National Park. What makes this plant unique is the high quality of the raw water coming into the facility, which, though it has physical-chemical processes, operates without adding any reagents.

Seawater desalination plant in Melilla

- Instalación desaladora de agua de mar

The Seawater Desalinization Plant in Melilla was designed and built by Cadagua under a concessional contract that included 12 years of Operation and Maintenance. The water production capacity of the desalinization plant is 7,100,000 m3 per year, and it is used for the potable water supply for Ciudad Autónoma. It is the main supply resource for the city, making up over 60% of the entire water supply. It has open intake through an underwater outfall, pretreatment based on a two-phase sand filtration stage, and cartridge filtration prior to the osmosis stretchers with energy recovery by means of Pelton turbines.

Wastewater treatment plant in Marismas del Odiel

- Estación de depuración de aguas residuales

The Punta Umbría WWTP in Huelva serves the approximately 142,000 residents of the municipalities of Punta Umbría, Aljaraque, and El Rompido. It represents an environmental improvement in an area of great ecological value, as are the Marismas del Odiel. It incorporates tertiary treatment, which enables reusing the water in public gardening, agricultural irrigation, and golf courses in the area.

Wastewater treatment plant in Janowek – Wroclaw

- Estación de depuración de aguas residuales

Expansion and remodeling of the Wrocław WWTP, a noteworthy construction project in 2 significant ways: ENVIRONMENTAL IMPROVEMENT: this has largely contributed to halting the environmental wear of the Odra River, and thus the Baltic Sea, by obtaining treated water of a higher quality with more restrictive guarantees. In addition, the plant has considerably increased its efficiency by means of co-generation installed based on the plant’s biogas, which covers up to 70% of the demand for electrical energy for its operation. A WORK OF GREAT IMPORTANCE: the magnitude of the construction is translated into figures and results. Figures: Six (6) digesters that are 25 m tall with a unit volume of 6,500 m3 or 48.7 million m3 of concrete used during the construction work. Results: The Wrocław Sewage Treatment Plant won the 10th annual “Lower Silesia Construction of the Year” in the category of “Engineering Construction” in 2013, as well as the “2012 Building of the Year” award in the category for “wastewater treatment.”

ETAP International Paper

- Industrial wastewater purification station

Expansion of the capacity of the aerobic purification system with MBBR technology and clarification with DAF flotation by using anaerobic Biopaq IC technology, and transformation of the MBBR into conventional activated sludge with secondary decantation. The biogas created is cleaned and conditioned to be burned in boilers.

Industrial wastewater treatment plant at Mahou-San Miguel Alovera

- Industrial wastewater purification station

Modernization of existing anaerobic treatment systems, adding a Biopaq IC, dismantling two old UASBs to turn them into a backup tank.

Seawater desalination plant in Madinat Yanbu Al-Sinaiyah

- Instalación desaladora de agua de mar

Cadagua’s first project in the Middle East (the Red Sea) for an industrial Client in a petrochemical complex with high technical and operational requirements.

Wastewater treatment plant at the Lyna (Olsztyn) Sludge Drying and Incineration Plant

- Estación de depuración de aguas residuales

- Secado Térmico

Design and execution of the Sludge Drying and Incineration Plant at the Olsztyn WWTP. The Plant, which was designed and built to treat 12,000 T/year, is one of the first facilities in Poland that strictly incinerates sludge coming from a purification system. The thermal processes applied reduce the sludge by up to ten times its original weight.

Wastewater treatment plant in Lloret

- Estación de depuración de aguas residuales

Wastewater treatment plant in Lledoner

- Estación de depuración de aguas residuales

Wastewater treatment plant in La Poveda

- Estación de depuración de aguas residuales

This important work on the Isabel II Canal will enable doubling the capacity of the plant’s daily treatment. Operations originally began in 1991 with a capacity of 13,000 m3/day. Once completed, the WWTP has come to purify 21,500 m3 per day.

Wastewater treatment plant in La Gavia

- Estación de depuración de aguas residuales

Water from Cuenca del Tajo, S.A. awarded Cadagua the bid for expanding tertiary treatment at the La Gavia WWTP in Madrid. Advanced treatment consisting of physical-chemical processes, sand filtration, final filtration with microsieves, and ultraviolet disinfection ensures reusable water by meeting with all quality objectives.

Wastewater treatment plant in Hostalric

- Estación de depuración de aguas residuales

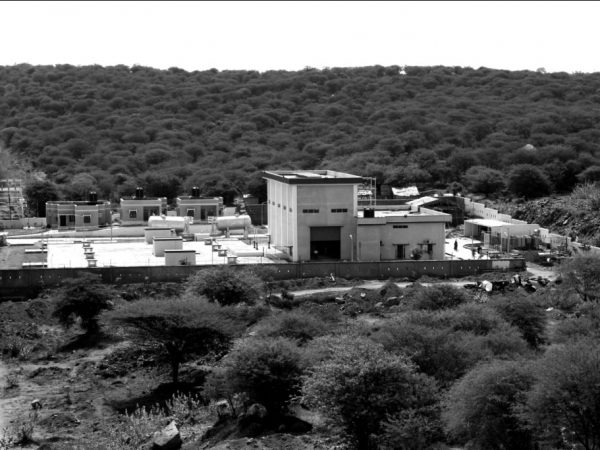

Drinking water treatment plant at Hogenakkal

- Estación de tratamiento de aguas potables

Located in a remote and environmental sensitive place in Tamil Nadu, south India. The project provides drinking water to almost 3 million inhabitants in a rural area. It incorporates flat bottom clarifiers to deal with variable raw water quality depending on the monsoon season. The project includes the river water abstraction, 11 km pipeline, 3 pumping stations and 3 water reservoirs.

Industrial wastewater treatment plant in La Alqueria

- Industrial wastewater purification station

Anaerobic Biopaq IC reactor to discharge existing aerobic treatment.

Industrial wastewater treatment plant at Heineken Valencia

- Industrial wastewater purification station

Total renovation of the existing UASB built in 1993.

Industrial wastewater treatment plant at Kimberly-Clark (Barrow)

- Industrial wastewater purification station

The Kimberly Clark purification system in Barrow (the United Kingdom) effectively confirmed the trust put in Cadagua by the multinational Kimberly Clark, a trust that later translated into a third contract in their factory in London. The uniqueness of discharge from this sort of plant translates into a very specific design that ensures the generation of activated sludge with excellent decantability. Likewise, the design incorporates an influent refrigeration system to minimize the biomass’s thermal socks.

Industrial wastewater treatment plant at Kimberly-Clark (Aranguren, Vizcaya)

- Industrial wastewater purification station

In 1999, the purification system at Kimberly Clark’s paper mill in Aranguren marked the first of three successful contracts to purify wastewater from several other of the multinational Kimberly Clark’s tissue paper factories. Two of them were located in the United Kingdom.

Industrial wastewater treatment plant at Heineken – Madrid

- Industrial wastewater purification station

After various interventions carried out by Cadagua, the plant consists of anaerobic treatment by means of Biopaq IC and aerobic biological treatment with biological elimination of nitrogen and phosphorus, discharging the water into waterways.

Industrial wastewater treatment plant at Kimberly Clark – Northfleet (Bluewater)

- Industrial wastewater purification station

Once more, the Kimberly Clark group put their trust in Cadagua to meet demanding limits for discharge in the River Thames. The project was carried out under the EPC method, including civil construction. Additionally, the quality of the water supply to the factory taken from wells was expanded and improved, including a reverse osmosis plant to reduce salinity.

Wastewater treatment plant in Guillarei

- Estación de depuración de aguas residuales

Given its size and the sorts of processes it uses, the Guillarei WWTP is one of Cadagua’s most significant projects. This plant treats wastewater from the region of A Louriña, specifically the municipalities of Salceda de Caselas, Tui, Porriño, and Mos. It can treat up to 40,000 m3/d, thanks to its complete treatment line that includes anaerobic sludge digestion, energy recovery via co-generation with a 330 kWe biogas motor, and low-temperature range thermal sludge drying with a drying capacity of up to 9,000 tons of wet sludge a year.

Industrial wastewater treatment plant at Heineken

- Instalación desaladora de agua de mar

“Water enters the intake building and bar screen. There are two dynamic sieves plus one emergency sieve and a solids compactor feedscrew. Biological reactor: two lines consisting of a low anoxic and oxic tank with air supplied by blowers. Secondary decanting: two circular secondary decanters with a moving bridge and a diameter of 16.6 m. Discharge from septic tanks: discharge goes through a compact sieve and from there to a pumping well that sends the water to the pretreatment arrival chamber. There are nine pumping stations located in different areas to boost the intake to be treated at the plant. There are two dynamic sieves plus one emergency and a solids compactor feedscrew in the intake building. The plant has a longitudinal sand sifter and sorter, where sedimented fats go to an excavation well and sands to a sand sorter. Biological reactor: two lines consisting of a low anoxic and oxic tank with air supplied by blowers. Secondary decanting: two circular secondary decanters with a moving bridge and a diameter of 16.6 m. Sludge thickening by means of two thickeners by means of gravity and sludge dehydration with a filter press.”

Industrial wastewater treatment plant in Font Salem Santarem (Portugal)

- Industrial wastewater purification station

The Damm group once again entrusted Cadagua with the purification plant for their first beer factory outside of Spain, with a demanding limit on discharge into public waterways.

Industrial wastewater treatment plant at Cobega (Coca Cola) Montornes-Martorel

- Estación de depuración de aguas residuales industriales

Purification system for discharge into waterways consisting of anaerobic treatment by means of Biopaq IC and aerobic treatment by means of activated sludge.

Industrial wastewater treatment plant at Cobega – Tacoronte

- Estación de depuración de aguas residuales industriales

After the successful completion of a project at their plant in Barcelona, Cobega entrusted Cadagua with the design, construction, start-up, and subsequent operation of this plant on the island of Tenerife.

Wastewater treatment plant in Galapagar-Torrelodones

- Estación de depuración de aguas residuales

This expansion of the WWTP represents a 50% increase in the plant’s capacity. It undoubtedly highlights the use of Biofilter technology in the purification process, showing once again Cadagua’s virtuosity in the wide range of purification technologies available.

Industrial wastewater treatment plant at Font Salem S.A. – El Puig

- Estación de depuración de aguas residuales

Biological biogas washing generated in a Biopaq IC reactor to be used in factory boilers.

Wastewater treatment plant in Galindo

- Estación de depuración de aguas residuales

The Galindo wastewater treatment plant located in Sestao is undoubtedly the Consorcio de Aguas de Bilbao-Bizkaia outstanding example of work in sanitation. Cadagua played a vital role in some of the most important phases of its growth and evolution. Highlights include the design and completion of the complex, versatile secondary treatment system, including the rectangular secondary clarifiers, as well as the execution of one of its sludge incinerators. This WWTP now treats 350,000 m3 of wastewater daily, and it is an essential infrastructure in the process of regeneration of the Estuary of Bilbao.

Industrial wastewater treatment plant in García Carrión Daimiel

- Industrial wastewater purification station

Transformation of an aerobic purification system by means of SBR for an anaerobic one by means of Biopaq IC, reducing operation costs. The biogas generated represents a saving of approximately 30% of the natural gas used up and manufacturing.

Industrial wastewater treatment plant at García Carrión S.A.(citrus fruits from Andévalo)

- Estación de depuración de aguas residuales industriales

Transformation of an MBR aerobic purification system into an anaerobic one using Biopaq IC, reducing operation costs. The biogas generated represents a savings of approximately 30% of the natural gas used up in manufacturing.

Wastewater treatment plant in Guadalajara

- Estación de depuración de aguas residuales

The Guadalajara WWTP was designed and built by Cadagua, and it not only complies with European Directive requirements on municipal wastewater treatment, but it also allows for improved performance in removing nutrients with biological methods in accordance with the Hydrological Program Tajo Basin requirements, which is even more restrictive in this regard than European legislation. Since the plant was inaugurated, the environmental quality of the Henares River has notably improved, thereby helping social and economic development with respect to the environment.

Seawater desalination plant in Granadilla

- Instalación desaladora de agua de mar

The new seawater desalinization plant in Granadilla de Abona serves a population of 56,000 people and will increase irrigation resources for agriculture in the region. In its first phase, it is generating 14,000 m³ per day, which can expand up to 21,000. This desalinization plant includes seawater collection be means of 6 wells near the coast 63 meters deep, a deposit of product water, a pumping station, piping, and drawing and transporting the product water to the 10,000-cubic-meter hub warehouse.

Wastewater treatment plant in Gorzow Wielkopolski

- Estación de depuración de aguas residuales

Expansion and Modernization of the Sludge Line at the municipal wastewater treatment plant in Gorzów Wielkopolski. The construction has involved significant modernization of the plant through various interventions: • Demolition and construction of new structures (digesters) • Remodeling the thickening building • A new facility for thickening and dehydration (by centrifuges) • Construction of new (dehydrated) sludge storage deposits • Renovation of facilities for electric co-generation and biogas management.

Wastewater treatment plant for Thermal Sludge Drying and Biogas Management at Cos

- Estación de depuración de aguas residuales

The Thermal Drying and Biogas Management facility at the COŚ WWTP was one of Cadagua’s first projects in Poland. The thermal drying system consists of three independent drying lines (2+1R), with an evaporation capacity of 3,050 kg/h of water. The end product, granules with a high energetic value that are hygienically safe, are for reuse at the plant in different capacities, such as fuel.

Wastewater treatment plant in Gavá – Viladecans

- Estación de depuración de aguas residuales

Cadagua took on this major modernization project for the Gava Viladecans treatment plant in order to ensure discharge meets the new European guidelines for discharge in sensitive areas and to allow them to be reused in the natural environment. The obsolete conventional active sludge processes were converted into two parallel processes: a membrane bioreactor (MBR) and integrated fixed-film activated sludge (IFAS). Each line has a capacity of 32,000 m3/d.

Industrial wastewater treatment plant in Fini Golosinas

- Estación de depuración de aguas residuales industriales

Transformation of aerobic purification system with SBR technology into an anaerobic purification system with Biopaq IC and Biological activated sludge, expanding capacity and drastically reducing operating costs.

Industrial wastewater treatment plant at Europac – Dueñas

- Estación de depuración de aguas residuales industriales

Expansion of the existing purification system by installing an anaerobic Biopaq IC reactor.

Industrial wastewater treatment plant at Europac – Alcolea

- Estación de depuración de aguas residuales industriales

Updates to the purification plant, including Biopaq IC and strengthening the existing aerobic one.

Industrial wastewater treatment plant in Estrella de Galicia

- Estación de depuración de aguas residuales industriales

Compact purification system for discharge into sewer pipes, treating 3,000 m3/day on a plot of just under 600 m2. As it is integrated in the urban hub, it includes complete treatment for odors to eliminate any sort of environmental impact. It includes biological biogas washing, Thiopaq.

Drinking water treatment plant in Entralgo

- Estación de tratamiento de aguas potables

A plant that treats water coming from the collection of La Coruxera, consumed in the Council of Langreo and part of the council of Mieres. It has a treatment capacity of 500 liters per second.

Drinking water treatment plant in Eguillor

- Estación de depuración de aguas residuales

This treatment plant, located 7 km from the supply source, continually treats the waters coming from the Arteta spring.

Industrial wastewater treatment plant in EMACSA (Burns Philp Food)

- Estación de depuración de aguas residuales industriales

Wastewater treatment plant in El Berro

- Estación de depuración de aguas residuales

This small WWTP, 80% financed by the European Union’s Cohesion Fund, is a good example of the wide range of sizes and solutions that Cadagua offers. The plant incorporates a tertiary treatment system by means of filtration and disinfection that surpasses the quality parameters set by European legislation. The plant also has environmental protection measures and is integrated into the picturesque landscape in the natural region of the Sierra Espuña.

Drinking water treatment plant in El Andévalo Occidental

- Estación de tratamiento de aguas potables

The Andévalo Occidental WTC has substantial improvement in the quality and quantity of hydraulic resources from the Andévalo region. Located in the areas around la Puebla de Guzman, it enables treating 750 m3 of water per hour from the Andévalo reservoir.

Wastewater treatment plant in Ibiza

- Estación de depuración de aguas residuales

Industrial wastewater treatment plant in Font Salem (Salem)

- Estación de depuración de aguas residuales industriales

Changing the anaerobic UASB reactor our for a Biopaq IC. In a later intervention, biological biogas washing, Thiopaq, was incorporated.

Industrial wastewater treatment plant at Damm S.A. – El Prat de Llobregat

- Estación de depuración de aguas residuales industriales

The long, fruitful relationship between Cadagua and DAMM began in the year 1998 with the total remodeling of the purification system at the Prat factory in the area around Barcelona’s airport. Back then, along with other interventions, 2 anaerobic reactors capable of treating 40 tons of DQO per day were installed. Later, in 2008, the capacity was increased to 72 tons, and in 2011, the Biogas Thiopaq washing was included for better energy usage and reducing the facility’s carbon footprint. Since then, the DAMM group has trusted Cadagua for purification systems of discharge in several of its factories.

Wastewater treatment plant in Crispijana

- Estación de depuración de aguas residuales

The Crispijana WWTP treats wastewater from Vitoria-Gasteiz. Since its inauguration in 1984, it has been continually updated and expanded. In 1998, Cadagua took over designing and building the secondary treatment system with nutrient removal.

Wastewater treatment plant in Coria

- Estación de depuración de aguas residuales

The Coria WWTP awarded to Cadagua and Ferrovial by the public company ACUAES provides a solution for Coria’s wastewater in Cáceres. The idea behind the expansion was developed considering the need for keeping the existing facilities in operation, the process’s logical sequence, and the topographical and geotechnical characteristics of the terrain.

Wastewater treatment plant at Copero II

- Estación de depuración de aguas residuales

The Copera Treatment Plant has a current capacity of 255,000 m3/day and purifies wastewater from the southern basin of Seville, the town of Dos Hermanas, and the La Isla industrial complex. The primary treatment dates back to 1987 and 1993. Cadagua took over the design and construction of biological treatment and the secondary clarifier in the year 2000.

Industrial wastewater treatment plant at Condesan

- Estación de depuración de aguas residuales industriales

The Condesan Purification System in Santomera (Murcia) purifies wastewater from processing citrus fruits. Pretreatment by using dissolved air floatation eliminates fibers and essential oils that confer a certain toxic element to these waters. After pretreatment and homogenization, the purification system combines anaerobic IC technology with a second phase of conventional activated sludge to ensure quality discharge.

Wastewater treatment plant in Comillas y Ruiloba

- Estación de depuración de aguas residuales

This modern compact facility is characterized by the use of Biofiltration technology by means of the BIOSTYR process. Upflow biofiltration that combines the simultaneous process of nitrification and denitrification. It is an underground facility that has minimal environmental impact, as it minimizes emissions of noises, smells, aerosols, and enables perfect, harmonious integration into the landscape.

Seawater desalination plant at Dhekelia I & II

- Estación de depuración de aguas residuales

The first large Ocean Water Desalinization Facility on the island of Cyprus, built in two phases in the record time of 18 months (Phase I) under a BOT scheme. Over time, it was remodeled to introduce new technologies, reducing operation costs, and expanded in capacity to 60 MLDs.

Wastewater treatment plant in Ciudad Real

- Estación de depuración de aguas residuales

Ciudad Real’s WWTP, which has a flow of 41,000 m3/d, provides a solution for the equivalent of more than 200,000 residents of Ciudad Real, Miguelturra, and Poblete. In its layout, the purification system incorporates future expansion for the equivalent of 410,000 people, and it features anaerobic digestion and biogas co-generation, among other technologies.

Wastewater treatment plant in Chorzów Klimzowiec

- Estación de depuración de aguas residuales

Expansion and modernization of the “Klimzowiec” WWTP, located at the border between two cities, Chorzów (the mechanical part of treatment) and Katowice (biological treatment with biological elimination of nutrients and sludge treatment). The purification system is one of the largest in Poland and serves around 200,000 residents. Thanks to this intervention and applied technologies, the Klimzowiec WWTP is now a modern plant that meets the highest technical standards for construction and automation in the wastewater treatment sector. The current co-generation generates the heat necessary for over 90% of the plant’s total demand and produces enough electrical energy to cover more than 70% of the demand for electricity in the process.

Wastewater treatment plant in Chipiona

- Estación de depuración de aguas residuales

The Agencia Andaluza de la Consejería de Medio Ambiente de la Junta de Andalucía awarded Cadagua the Design and Construction of this major treatment plant, which offers a solution for the waste produced by 150,000 inhabitants. With a low load extended aeration process, the WWTP accounts for the particularities arising from the large fluctuations in population that Chipiona experiences over the year.

Wastewater treatment plant in Butarque II

- Estación de depuración de aguas residuales

The Butarque WWTP is one of Cadagua’s milestones. Located on the right bank of the Manzanares River, it treats water from the districts of Villaverde, Usera, Latina, Carabanchel, and Moncloa-Aravaca. This large treatment plant has many special features, but the 4 digesters with a unit volume of 10,200 m3 and the co-generation system with a 1,800 kWe motor are especially noteworthy. In 1974, Cadagua built the 8 primary clarifiers, and in 2005, we took on the design and construction of the covering and the odor treatment of the primary clarifiers.

Industrial wastewater treatment plant in Cervezas Estrella de Levante – Espinardo

- Estación de depuración de aguas residuales industriales

Compact purification system for discharge into sewer pipes, treating 2,400 m3/day. It has biological biogas washing generated for use in microturbines by means of Thiopaq technology.

Industrial wastewater treatment plant in Cervecera Canarias

- Estación de depuración de aguas residuales industriales

Conventional in-brewery purification system by means of Biopaq IC, with exhaustive environmental impact monitoring (odors and noise) by being located in the heart of the city, totally surrounded by housing.

Wastewater treatment plant in Besòs

- Estación de depuración de aguas residuales

It serves a population of 2,800,000 residents (70% of Barcelona’s population). It is built inside a small space with a roof used as a public park (Forum Universal). It features a suspended solids separation process by means of clarifiers with compact lamellae, with solid concentrator hoppers.

Industrial wastewater treatment plant in Celesa (Tortosa)

- Estación de depuración de aguas residuales industriales

The Miquel y Costas group entrusted Cadagua with the purification system at their factory in Tortosa with discharge into public waterways. The main handicap to the design was the limited amount of space available, addressed with biological reactors with an elevated water level and clarification by means of DAF technology.

Wastewater treatment plant in Baix Llobregat

- Estación de depuración de aguas residuales

Sludge treatment in the biggest modern WWTP in Spain, which serves 2.3 million residents. It incorporates advanced solutions for recovering energy and sludge drying.

Wastewater treatment plant in Arroyo Culebro

- Estación de depuración de aguas residuales

Given its size and the sorts of processes it uses, the Arroyo Culebro Cuenca Media Alta WWTP is one of Cadagua’s most significant projects. Located in the Manzanares river basin in the municipality of Pinto, it treats wastewater from Parla and Fuenlabrada. It can treat up to 129,600 m3/d and produce 30,240 m3/d of regenerated water for use in irrigating parks and gardens. Its outstanding two-stage biological treatment with biological removal of nitrogen and phosphorus, its 4 secondary clarifiers 50 meters in diameter, and energy recovery of biogas produced by anaerobic digestion to supply a good part of the energy needed at the WWTP.

Wastewater treatment plant in Arenales – Elche

- Estación de depuración de aguas residuales

The use of MBR technology provided by Cadagua at the Arenales del Sol WWTP has allowed it not to occupy the area of the old purification system, such that during its construction operations were not interrupted, assuring quality discharge at all times and eliminating harmful environmental impact. The process was modeled and simulated using the WEST platform, and the results were used to explore their behavior under different modes of operation.

Wastewater treatment plant in Arazuri

- Estación de depuración de aguas residuales

The Arazuri WWTP treats wastewater generated in the Pamplona region and discharges waters into the Arga River. The primary treatment system dates back to 1990. in 1999, Cadagua took over design and construction of the biological treatment system, which included the removal of nutrients and anaerobic digestion with subsequent co-generation and energy recovery. Of particular note are the 6 large secondary clarifiers that are 48 meters in diameter and have a capacity of 7,700 m3.

Wastewater treatment plant in Antofagasta

- Estación de depuración de aguas residuales

It provides services to some 130,000 residents of the city of Antofagasta. One of the first WWTPs in LATAM with biological treatment of activated sludge.

Wastewater treatment plant in Campo de Dalías

- Estación de depuración de aguas residuales

Three plants with tertiary wastewater treatment to be reused for irrigation on golf courses and for gardens. They produce 28,560 m3/day for reuse by means of membrane filtration processes (MF + OI).

Drinking water treatment plant in la Ribera

- Estación de tratamiento de aguas potables

Alzira’s WTC, designed and built by Cadagua, addresses a historical problem in the area, which is the continual degradation of the underground water quality, a result of agricultural activity.

Seawater desalination plant in Al-Zawrah

- Instalación desaladora de agua de mar

Design and Construction of a seawater desalination plant in the Emirate of Ajman for the Federal Electricity & Water Authority (FEWA). Cadagua led this contract, which, with a capacity of 45,560 m3 per day, supplies water to a population of about 230,000 people. The advanced pretreatment combines Dissolved Air Flotation technology with Ultrafiltration for the purpose of ensuring high-quality water for Osmosis.

Wastewater treatment plant in Almendralejo

- Estación de depuración de aguas residuales

The Almendralejo WWTP in Badajoz was built on the same plot of land as the previous purification system. It required a detailed execution in phases to ensure that the given quality parameters were being met at all times. Its unique features include a lamination tank for high-load wastewater and the energy use of biogas produced during digestion.

Wastewater treatment plant in Aljarafe Guadalquivir

- Estación de depuración de aguas residuales

The Aljarafe treatment plant, managed by the public company Aljarafesa, was built to treat the water from some twenty municipalities in the region of Aljarafe in Seville. Cadagua took charge of the design and construction of physical-chemical treatment as well as secondary treatment of the construction completed in 1996.

Wastewater treatment plant in Albufera Sur

- Estación de depuración de aguas residuales

The Albufera WWTP in the La Ribera Baixa Region serves the municipalities of Alginet, Almussafes, Benifaió, and Sollana. This major treatment plant is a vital part of maintaining the Albufera’s good ecological conditions, and it has been in operation for over 10 years, treating wastewater by using a complete process that includes the removal of N and P nutrients, final water disinfection, and anaerobic stabilization of the sludge and energy recovery of biogas to minimize the plant’s energy consumption.

Seawater desalination plant in Agragua

The Agragua Desalinization Plan in Gran Canaria was a success in the year 1991, as it was a concessional project that included 7 years of Operation and Maintenance. Subsequently, in the year 1998, it was expanded by Cadagua, including an extension of the concession for another 15 years.

Drinking water treatment plant in Abrera

- Estación de tratamiento de aguas potables

The Llobregat Treatment Station for Potable Water, located in the municipal district of Abrera (Barcelona) and in operation since 1980, makes up one of the basic elements for the potable water supply in the area of Barcelona thanks to the 200,000 m3 of potable water it produces daily.

Seawater desalination plant in Lanzarote

- Instalación desaladora de agua de mar

Seawater desalination plant in La Aldea

- Instalación desaladora de agua de mar

The La Aldea desalination plant began operating in January 2001 with an operating contract with the Tenerife Water Board and initial production of 5,000 m3/day with a single frame. Subsequently, in 2010, another 5,000 m3/d (two 2,500 lines) facility was attached to the annexed vessel for purely agricultural use. In 2016, energy improvements were made at the 2nd ERIS facility, allowing 2,500-5,000 m3/d to be treated as needed.

Seawater desalination plant in Granadilla

- Instalación desaladora de agua de mar

Seawater desalination plant in Formentera

- Instalación desaladora de agua de mar

The desalinization plant in Formentera, Designed and Built by Cadagua in the year 1995, has for many years been the only potable water supply for the island. Subsequently, in 2013, Cadagua carried out remodeling to ensure demand during peak tourism season.

Industrial wastewater treatment plant in Cobega Tacoronte

- Estación de depuración de aguas residuales industriales

The Damm group once again placed their trust in Cadagua for the purification plant for their first beer factory outside of Spain, with a demanding discharge limit into public waterways.

Industrial wastewater treatment plant in Cobega

- Estación de depuración de aguas residuales industriales

Thermal drying in Loeches

- Secado Térmico

A plant located in Loeches in the east of Madrid, where sludge from different treatment plants of the Community of Madrid is transferred for treatment. The facility also includes a 50,000 Tn/year capacity treatment mud composting plant and a pre-treatment waste dump for 15,000 Tn/year. It also has 19 Mw of installed power in cogeneration composed of three 6 Mw unit power motor generators.

Seawater desalination plant in Alicante

- Instalación desaladora de agua de mar

The Ocean Water Desalinization Facility in Alicante, which has a capacity of 65,000 m3/day, was financed, Designed, and Built by Cadagua in 2003. Since then, for a concessional period of 15 years, Cadagua has been in charge of its Operation and Maintenance. It is characterized by having seawater intake through collection in deep wells (18 units) and 7 osmosis frames fed by several other high-pressure pumps with energy recovery by means of Pelton turbines.

Industrial wastewater treatment plant in Opel (Figueruelas)

- Estación de depuración de aguas residuales

Seawater desalination plant in Melilla

- Instalación desaladora de agua de mar

Drinking water treatment plant in Yalde

- Estación de tratamiento de aguas potables

Industrial wastewater treatment plant in Heineken

- Estación de depuración de aguas residuales

Seawater desalination plant in Valdelentisco

- Instalación desaladora de agua de mar

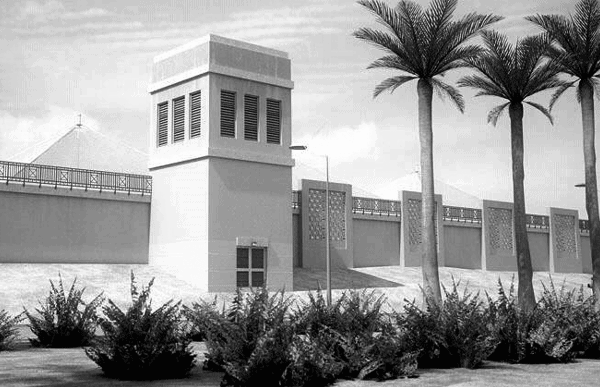

Seawater desalination plant in Ceuta

- Instalación desaladora de agua de mar

Ceuta’s desalinization plant was designed and built by Cadagua in 1998, under a concessional contract that included 20 years of Operation and Maintenance. Subsequently, in the year 2008, Cadagua took on its expansion to the current capacity of 30,000 m3/d, a figure greater than the city’s usual demand. It is undoubtedly a vital infrastructure for the Ciudad Autónoma de Ceuta’s supply. Thanks to this intervention, the use of freshwater coming from other sources, such as the Renegado and Infierno reservoirs, has gone down.

Wastewater treatment plant in Sant Joan de les Abadesses

- Estación de depuración de aguas residuales

Wastewater treatment plant in Vila-seca and Salou

- Estación de depuración de aguas residuales

Wastewater treatment plant in Ribes de Freser

- Estación de depuración de aguas residuales

Wastewater treatment plant in Vilafranca

- Estación de depuración de aguas residuales

Wastewater treatment plant in Port de Sant Miquel

- Estación de depuración de aguas residuales

Wastewater treatment plant in Planoles

- Estación de depuración de aguas residuales

Wastewater treatment plant in Mancomunada

- Estación de depuración de aguas residuales

Wastewater treatment plant in Núria

- Estación de depuración de aguas residuales

Wastewater treatment plant in Santa Margalida

- Estación de depuración de aguas residuales

Wastewater treatment plant in Nevà (Toses)

- Estación de depuración de aguas residuales

Wastewater treatment plant in Villapérez

- Estación de depuración de aguas residuales

Wastewater treatment plant in Sant Joan

- Estación de depuración de aguas residuales

Wastewater treatment plant in Gavia

- Estación de depuración de aguas residuales

Wastewater treatment plant in Madrid Sur

- Estación de depuración de aguas residuales

Wastewater treatment plant in Setcases

- Estación de depuración de aguas residuales

Wastewater treatment plant in Muro

- Estación de depuración de aguas residuales

Wastewater treatment plant in Sant Pau de Segúries

- Estación de depuración de aguas residuales

Wastewater treatment plant in Camprodon

- Estación de depuración de aguas residuales

Wastewater treatment plant in Llubí

- Estación de depuración de aguas residuales

Wastewater treatment plant in Santa Eulària

- Estación de depuración de aguas residuales

Wastewater treatment plant in Ripoll

- Estación de depuración de aguas residuales

Wastewater treatment plant in Can Fornaca

- Estación de depuración de aguas residuales

Wastewater treatment plant in Rejas

- Estación de depuración de aguas residuales

Wastewater treatment plant in Costitx

- Estación de depuración de aguas residuales

Wastewater treatment plant in Sant Josep

- Estación de depuración de aguas residuales

Wastewater treatment plant in Vilobí d’Onyar

- Estación de depuración de aguas residuales

Wastewater treatment plant in Valle la Orotava

- Estación de depuración de aguas residuales

Wastewater treatment plant in Algaida-Montuïri

- Estación de depuración de aguas residuales

Wastewater treatment plant in Riudellots de la Selva

- Estación de depuración de aguas residuales

Wastewater treatment plant in Caldes de Malavella

- Estación de depuración de aguas residuales

Wastewater treatment plant in Castellví de Rosanes

- Estación de depuración de aguas residuales

Wastewater treatment plant in Anglès

- Estación de depuración de aguas residuales

Wastewater treatment plant in Aiguaviva Parc

- Estación de depuración de aguas residuales

Wastewater treatment plant in Breda

- Estación de depuración de aguas residuales

Wastewater treatment plant in Avinyó

- Estación de depuración de aguas residuales

Wastewater treatment plant in Riudarenes

- Estación de depuración de aguas residuales

Wastewater treatment plant in Riells

- Estación de depuración de aguas residuales

Wastewater treatment plant in Gelida

- Estación de depuración de aguas residuales

Wastewater treatment plant in Paterna – Fuente del Jarro

- Estación de depuración de aguas residuales

Wastewater treatment plant in Maçanet Residencial

- Estación de depuración de aguas residuales

Wastewater treatment plant in San Pedro del Pinatar

- Estación de depuración de aguas residuales

Wastewater treatment plant in Rubí

- Estación de depuración de aguas residuales

Wastewater treatment plant in Maçanet de la Selva

- Estación de depuración de aguas residuales

Wastewater treatment plant in Terrassa

- Estación de depuración de aguas residuales

Wastewater treatment plant in Yecla

- Estación de depuración de aguas residuales

Wastewater treatment plant in Can Bossa

- Estación de depuración de aguas residuales

Wastewater treatment plant in Sils i Vidreres

- Estación de depuración de aguas residuales

Wastewater treatment plant in Cànoves i Samalús

- Estación de depuración de aguas residuales

Wastewater treatment plant in Portmán

- Estación de depuración de aguas residuales

Wastewater treatment plant in Sant Antoni de Vilamajor

- Estación de depuración de aguas residuales

Wastewater treatment plant in Vilaller

- Estación de depuración de aguas residuales

Wastewater treatment plant in La Unión

- Estación de depuración de aguas residuales

Wastewater treatment plant in Senet

- Estación de depuración de aguas residuales

Wastewater treatment plant in Cala Sant Vicent

- Estación de depuración de aguas residuales

Wastewater treatment plant in El Pont de Suert

- Estación de depuración de aguas residuales

Wastewater treatment plant in Cala Llonga

- Estación de depuración de aguas residuales

Wastewater treatment plant in Fuente Álamo

- Estación de depuración de aguas residuales

Wastewater treatment plant in Durro

- Estación de depuración de aguas residuales

Wastewater treatment plant in Boí

- Estación de depuración de aguas residuales

Wastewater treatment plant in Cala Tarida

- Estación de depuración de aguas residuales

Wastewater treatment plant in Roldán, Lo Ferro, and Balsicas

- Estación de depuración de aguas residuales

Wastewater treatment plant in Barruera

- Estación de depuración de aguas residuales

Wastewater treatment plant in Vilanova del Vallès

- Estación de depuración de aguas residuales

Wastewater treatment plant in Sant Joan de Labritja

- Estación de depuración de aguas residuales

Wastewater treatment plant in Sant Antoni

- Estación de depuración de aguas residuales

Wastewater treatment plant in Foia de Castalla

- Estación de depuración de aguas residuales

Wastewater treatment plant in de Eivissa

- Estación de depuración de aguas residuales

Wastewater treatment plant in Jumilla

- Estación de depuración de aguas residuales

Wastewater treatment plant in Viseu Sul

- Estación de depuración de aguas residuales

Wastewater treatment plant in Los Alcázares

- Estación de depuración de aguas residuales

Wastewater treatment plant in San Javier

- Estación de depuración de aguas residuales

Wastewater treatment plant in Aulesti

- Estación de depuración de aguas residuales

Wastewater treatment plant at New Darsait STP

- Estación de depuración de aguas residuales

Wastewater treatment plant in Utebo

- Estación de depuración de aguas residuales

Wastewater treatment plant in Ría del Eo

- Estación de depuración de aguas residuales

Desalination Plant Al Ghubrah Oman

- Sustainability

Design, Construction, and Operation of one of the largest reverse osmosis desalinization plants in Oman. The Al Ghubrah Independent Water Project (IWP) is a pioneering project that stands out for its complex implementation, low energy usage, and advanced pretreatment system by means of Dissolved Air Flotation to ensure production under the worst seawater conditions.

Discover the projectHow Do We Innovate?

We develop tools for the simulation, management, and maintenance of WWTPs in order to put our know-how to use for each project. That way, we can optimize the biological processes at the different plants.

We also carry out research projects with advanced technologies, such as submerged membrane bioreactors (MBR), in aerobic and anaerobic conditions, anammox treatments in digestion returns, and in the main line, advanced oxidation processes for removing contaminants that are of growing concern, biofouling control at underwater intakes, remineralization with dolomites, energy optimization in reverse osmosis, and more.

In addition, we collaborate on internationally recognized projects, such as Hydrothermal Sludge Carbonization with the STORM project (in collaboration with the Massachusetts Institute of Technology), or those that are funded through the European Regional Development Fund, such as Membace, which uses ultrafiltration membranes to eliminate bacteria.

Our Commitment to the Environment

At Cadagua, we contribute to the conservation of natural resources through our activities’ environmental integration by designing, building, and operating sustainable plants.

The requirements stemming from our Integrated System for Quality, Environment, Energy, and R&D&I are the best guarantee we can offer our Customers, Administration, and Society regarding our commitment to sustainable evolution. To this end, we provide training in the engineering, construction, and operation of infrastructure for water and waste management, and we drive innovation in developing new technologies that can be used to protect the environment and prevent pollution.

We try to eliminate waste production, as the landfill is a last resort, and we encourage reuse and recycling of waste products as much as possible. Waste management must always be carried out while ensuring environmental protection, and as such, we use the best technologies available that are economically suitable.

In our commitment to improving environmental management, we’ve gone a step further by implementing and checking the environmental management system at the Valdelentisco Desalination Plant according to ‘Regulation (EC) No. 1221/2009, on the voluntary participation of organisations in a Community eco-management and audit scheme (EMAS)’ and Regulation (EU) No 2017/1505, which represents the highest level of environmental requirements at the European level, as it is the first desalination plant in Europe to meet these standards.

Subsequently, and continuing in this commitment, this environmental management system was implemented at the Aguilas-Guadalentín Desalination Plant. In order to comply with the EMAS requirement regarding public availability of the information in the Environmental Declaration, the Aguilas-Guadalentín Desalination Plant’s verified Environmental Statement is available below.

Companies cadagua and webber

PLW Waterworks, Our Subsidiary in the United States

We have more than 25 years of experience constructing water treatment plants.